The process of adding colorful designs or patterns in fabric is called textile printing and we get to do this using reliable ink. Such a process is greatly used to give that special look of clothes, curtains or any other textile. Manufacturers are able to produce large arrays of styles that appeal to a broad spectrum though the use of different printing techniques.

Screen printing is a type of stencil method. The stencil on the fabric is first placed, and then using a screen printing machine, ink pressed through it resulting in what you see. Lay the foil and use it to make really bright, in-your-face patterns. Digital printing is a more recent method in which the desired design can be printed directly onto the fabric from an electronic printer. It creates the possibility of printing extremely complex and colorful designs fast and at ease. Block printing is a type of stamping that has been around for thousands of years, in which ink or dye is stamped onto fabric using something like the carved wooden block shown above. The block is dipped into ink and pressed onto the fabric by hand, which makes a lovely pattern so opt for Home Textile fabric from SULY Textile.

One of the best things about digital printing is that it delivers stunning and glossy prints with rich and vibrant colors in screen printing can only be done to a certain level in terms of detail, but digital printing allows for highly detailed and intricate designs on the fabric. It is therefore a perfect choice of material to make some elegant and stylish garments from Cotton Yarn so opt for printmaking on fabric from SULY Textile.

This has the effect of making environmentalists happy when using water based inks. But they may not be quite as vibrant as some other types of ink. These inks are called discharge inks, and they remove the dye from your garment so that you can replace it with a new color. This technique works great especially with darker fabrics so it is widely used for designs of that style.

Another popular type of ink for t shirt screen printing is plastisol because it delivers bright colors, easy to print with and lasts well making the design last on wash after was. Maybe at the end, excellent colors that do not fade abruptly over time are characteristics for which pigment inks can be chosen when printing digitally. Because of printing fabric from SULY Textile, blend fibers are perfect for items that be in continued use or will require frequent washing.

As another interesting thought in textile printing, smart fabrics are made with it. The fabrics are not only beautiful, but smart; they fold tiny sensors right in that can be used to measure everything from heart rate and body temperature. They are relatively new and as such, still in the exciting development stage of textile industry unit: it is a smart fabric that uses nanotechnology to enable them to do many things including sense pain. They can be used throughout different sectors from medical purposes (as part of e-textiles) all the way through athletic wear so opt for block print fabric.

A method of traditional block printing that originates from many centuries ago in various places around the world. It is over 2000 years old and block printing techniques have been used to create complex designs very beautifully on fabrics which make them stand out. For example, in such lengths of tradition only underscore just how critical and treasured this art Printing fabric form has been some thousands years.

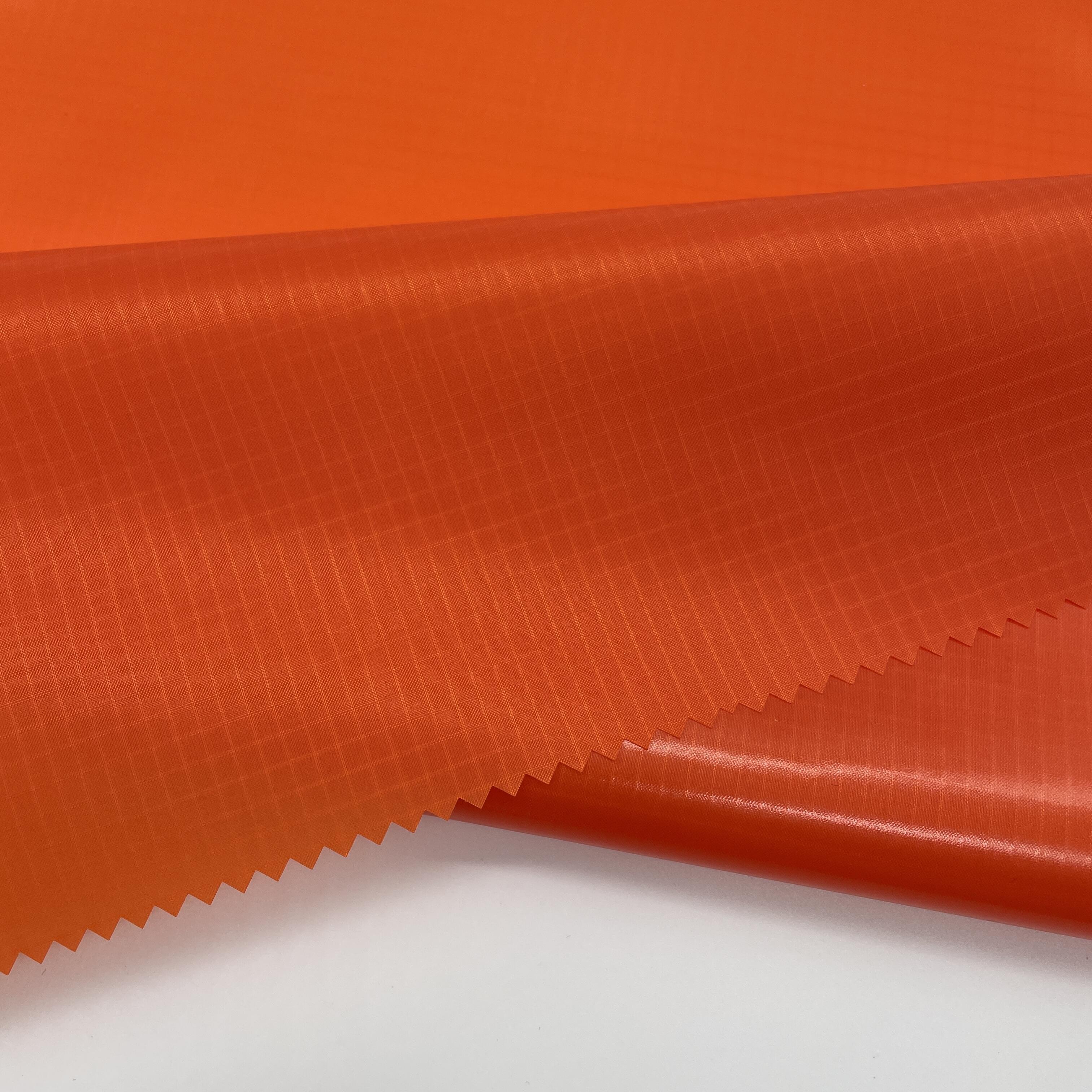

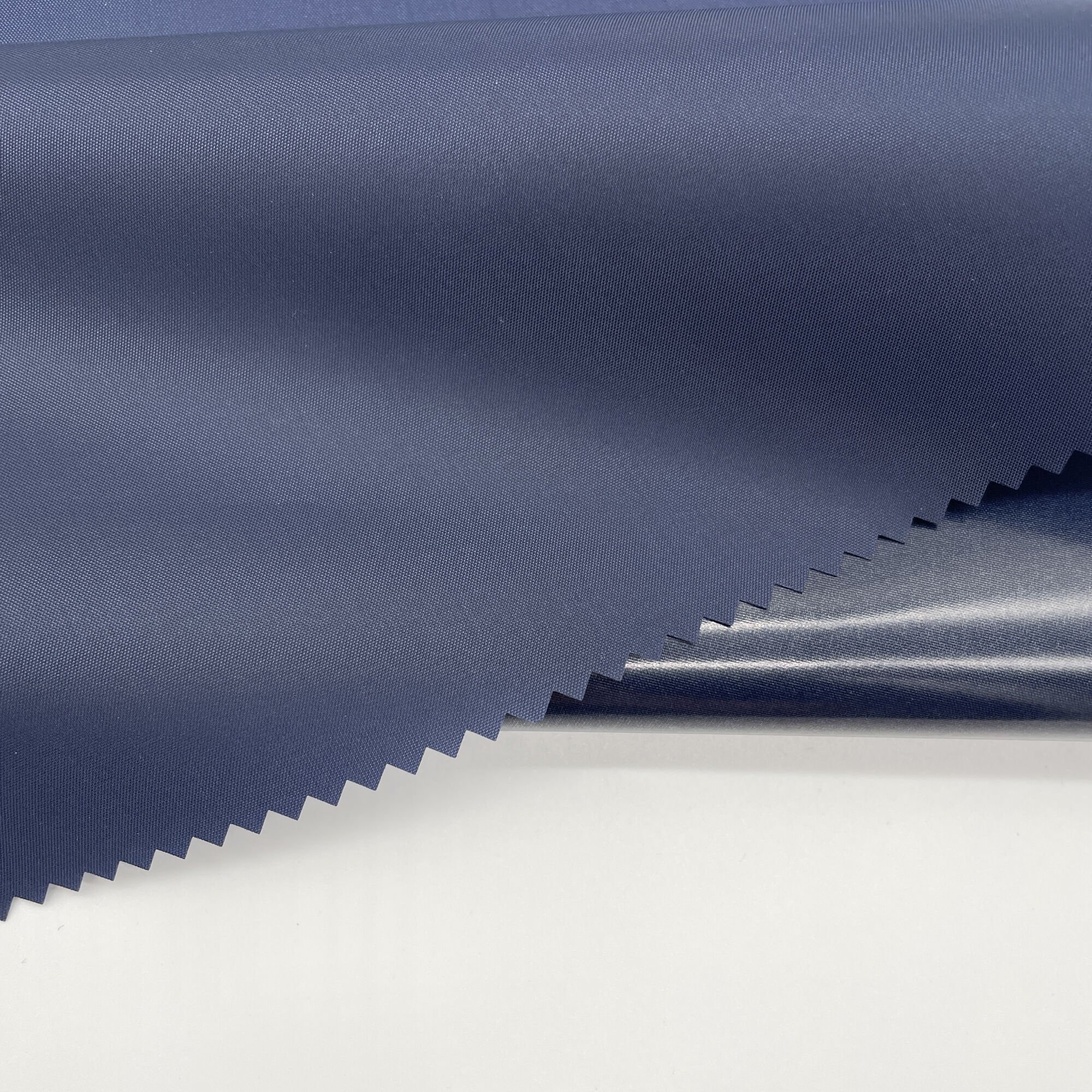

Suly Textile can Textile printing various types of custom-made fabrics to meet the demands of customers. Suly Textile is involved in the processing and sale of any kind of chemical fabric and blended fabric dyeing, coating, bonding and laminating. We specialize in functional fabrics such as strong water repellent fabric as well as high water column fabric. We also provide anti-static, anti-UV, moisture absorption, quick drying, anti-heat, flame retardant printed IFR and printed. Apart from that, we are able to accept low MOQ runs for printing. We provide a broad range of fabrics and can provide a one-stop solution.

The company is accredited through ISO9001, OEKO, SGS and other certifications. Additionally, we have our own testing center to test all different standards and also we have been working with our local certified 3rd party testing center who can give us Textile printing, exact and certified testing reports. Our sales staff can provide fast and accurate responses to customers' requests. Additionally, we have a shipping department who can provide excellent solutions for shipping in case customers are having issues with shipping.

Suly Textile, a professional fabric producer with a total of 20,000 sqm, has four lines of PU coated lines. The PU coated lines come from the United States and provide better quality coating. In addition, we have Textile printing of PVC coating lines which mainly produce outdoor fabrics bags, tents and industrial use. All of our technicians have more than 10 years experience in the field of textile production and are able to provide more efficient quality control and solutions. We are known for our nylon fabrics. We import dyes, greige and finishing products from Taiwan and finish them in our manufacturing facility.

Company main product: Softshell fabric, Hard shell fabric, RPET fabric Fabric for workwear, Bag fabric, Down jacket fabric, Aramid fabric Cordura Fabric that is Textile printing etc. In addition, our company offers custom-made service that can tailor-made to meet your requirements, such as Crinkled dyeing, Piece dyeing water repellent, printing Water column Teflon finishing, TPU coating, TPE coating, down proof, Anti-static, PU clear/milky coating and Flame retardant coating. High breathable coating, PA coating Cire, black-out coating, Embossed, Brushed, PVC lamination, PU transfer coating anti-UV, moisture absorption and quick drying, etc. Our product is widely utilized to make hiking jackets, skiing jackets, sports jackets down-proof outdoor clothing and children's sportwear, women's dress, etc.