The Origin of Nylon Material. Nylon is a fascinating type of filament with a unique origin. This material was developed during World War II when military personnel sought extremely tough and tear-resistant fabrics. The materials created by scientists are the strongest and most affordable, thanks to their innovative futuristic thinking. The following achievement is the creation of SULY Textile Nylon fabric. The military quickly embraced its potential and integrated it into various roles such as military gear, parachuting, and airplane tires. Nevertheless, its light weight and strength appealed to a wider audience beyond just the military, leading to global popularity, especially due to the ability to dye it in numerous patterns.

Today, nylon fabric is widely recognized in the fashion industry and is no longer limited to just stockings, as it is now used in a variety of items such as handbags, jackets, backpacks, and even shoes. Modern Life is renowned for these two virtues, which have been upheld since ancient times and have continued to thrive beyond previous generations. Maintaining nylon fabric is also simple. SULY Textile brushed nylon can withstand frequent machine washes without shrinking or fading like other fabrics, making it ideal for those with a busy wardrobe.

It is crucial to address this issue to ensure the sustainability of both nature and the textile industry. The material has many positive aspects, but the significant waste generated during SULY Textile nylon fiber production has detrimental effects on the environment. The practical implementation of Sustainability involves using recycled nylon to produce a significant portion, including old garments and ensuring they are recycled rather than wasted. Additionally, efforts are being made to innovate the manufacturing process of nylon in order to reduce environmental expenses as effectively as possible.

Progress in Nylon Textile: A novel bio-nylon fabric is becoming popular in the transition from petrochemical textiles to eco-friendly options derived from plant sources. Additionally, SULY Textile stretch textile development of smart textiles enables the use of soft materials as sensors to track biometric data or changes in environmental conditions.

To sum up, nylon is a material that transformed the textiles sector when it was first discovered. Originally SULY Textile nylon and spandex fabric designed for military purposes, this material quickly transitioned into the fashion industry due to its durability and practicality. In the face of ongoing reminders about environmental catastrophes, advancements and sincere efforts to tackle issues have led to significant progress in ensuring a promising future for nylon.

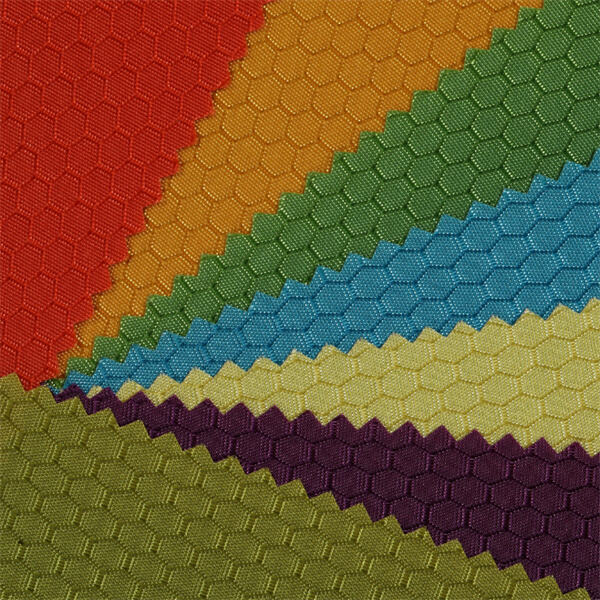

Suly Textile offers a wide selection of fabrics that can be customized to meet the requirements of different clients. The company is involved in the processing and selling of all kinds of chemical fabrics and Nylon textile, including dyeing coatings, bonding and laminating. We specialize in functional fabrics like strong water repellent fabrics as well as high-water column fabric. Also, we offer anti-static, anti UV, moisture absorption, quick drying, flame retardant, anti-heat printed IFR and printed. In addition, we offer low MOQ printing for printing. We offer a wide range of fabrics and offer a complete solution.

Suly Textile, a professional fabric manufacturer that covers 20,000 sqm, includes Nylon textile of PU coated lines. These PU coated lines come from the United States and provide better quality coating. We also have two PVC coating lines which produce textiles for outdoor jackets, bags as well as tents, industrial use and so on. Our technician all have over 10 years of experience in the field of textile production and can offer more quality-controlled service and solutions. Our nylon fabric is our strongest product and we import from Taiwan dye and greige, and finish it in our own production facility.

Our company offers an OEM service that can weave precisely to meet your needs such as Crinkled dyeing or Piece dyeing Water repellent, printing, Water column, Teflon finish, Nylon textile, TPE coating Anti-static, Downproof, PU milky/clear coating flame retardant, high breathable, PA, Black-out, Brushed, PVC lamination, PU transfer, Moisture absorption and quick drying, etc. In addition, our company offers the OEM service, which will weave specifically according to your needs, including Crinkled dyeing water repellent, printing water column, Teflon finishing, TPU coating, TPE coating, Down proof Anti-static, PU milky/clear coating, Flame retardant coating, High breathable coating, PA coating Cire, black-out coat embossed, brushed, PVC lamination and PU transfer coating anti-UV, moisture absorbing and quick drying, etc. Our product is widely utilized to make hiking jackets, skiing jackets, sport jackets, down-proof camping jackets, outdoor camping, children sportwear, women dress, etc.

The company is accredited through ISO9001, OEKO, SGS and other certifications. Additionally, we have our own Nylon textile to test all different standards and also we have been working with our local certified 3rd party testing center who can give us fast, exact and certified testing reports. We have our own experienced sales staff and we are able to give customers very fast and reliable information and address any customer concerns. We also have a team for shipping who can provide good solutions for shipping when the client is struggling with shipping.