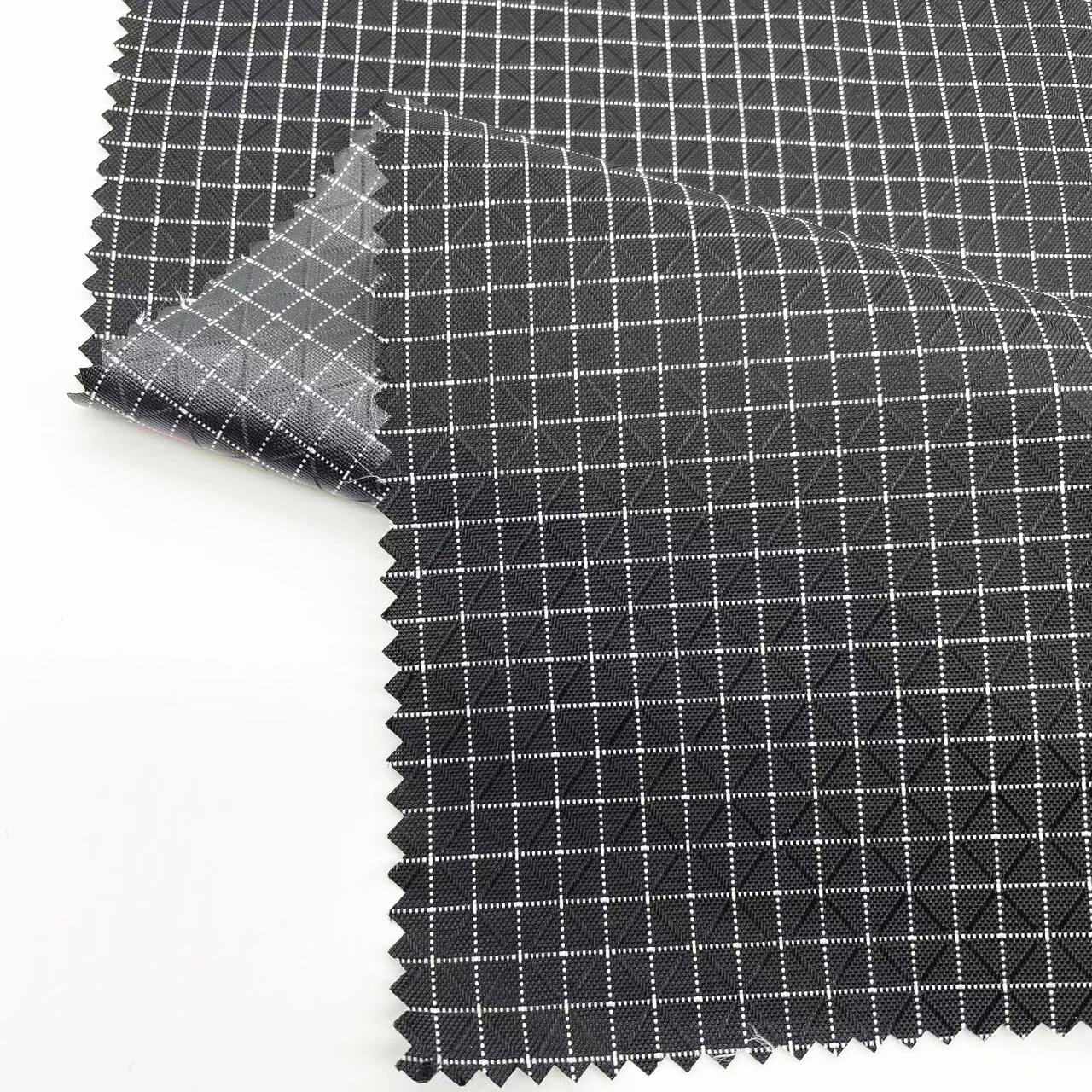

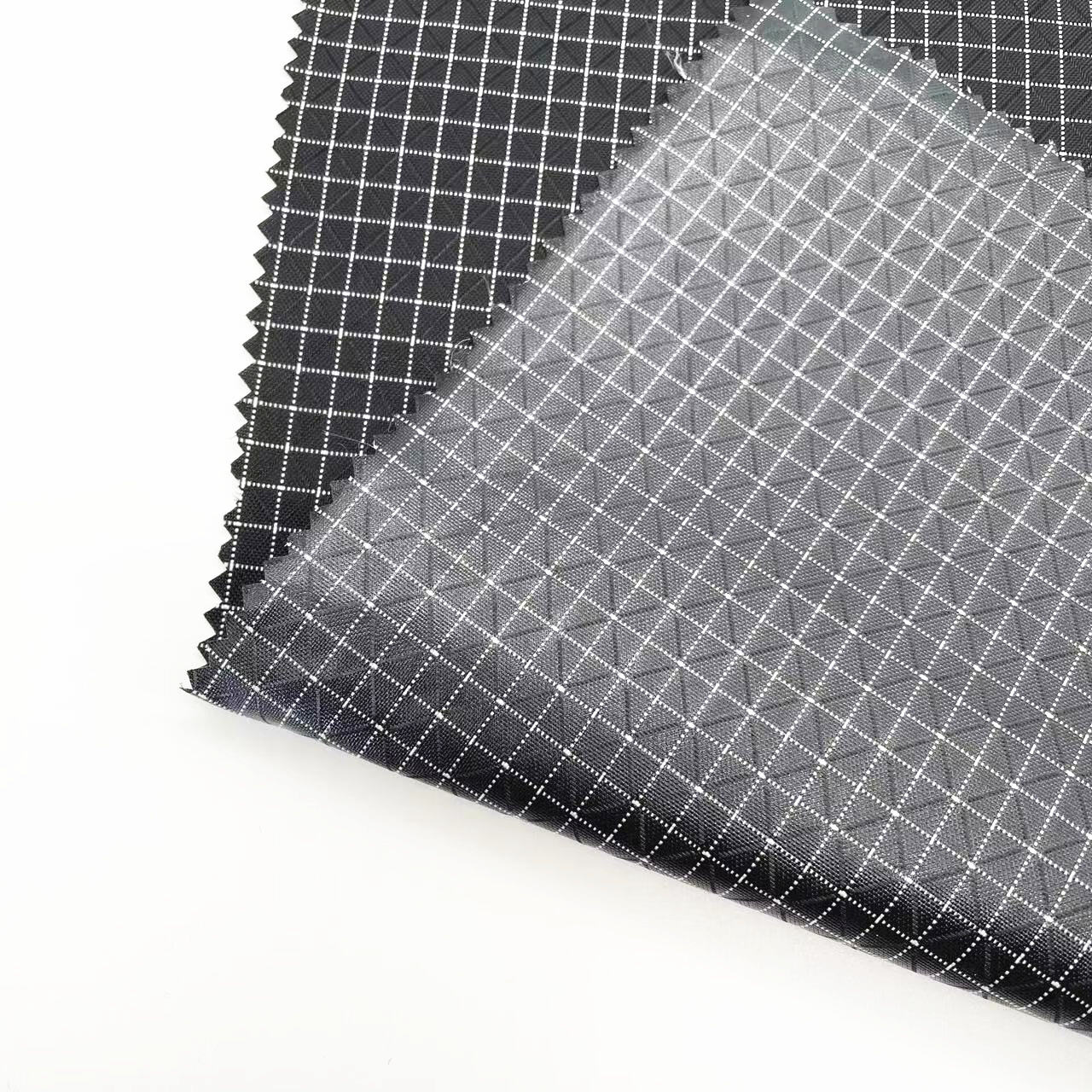

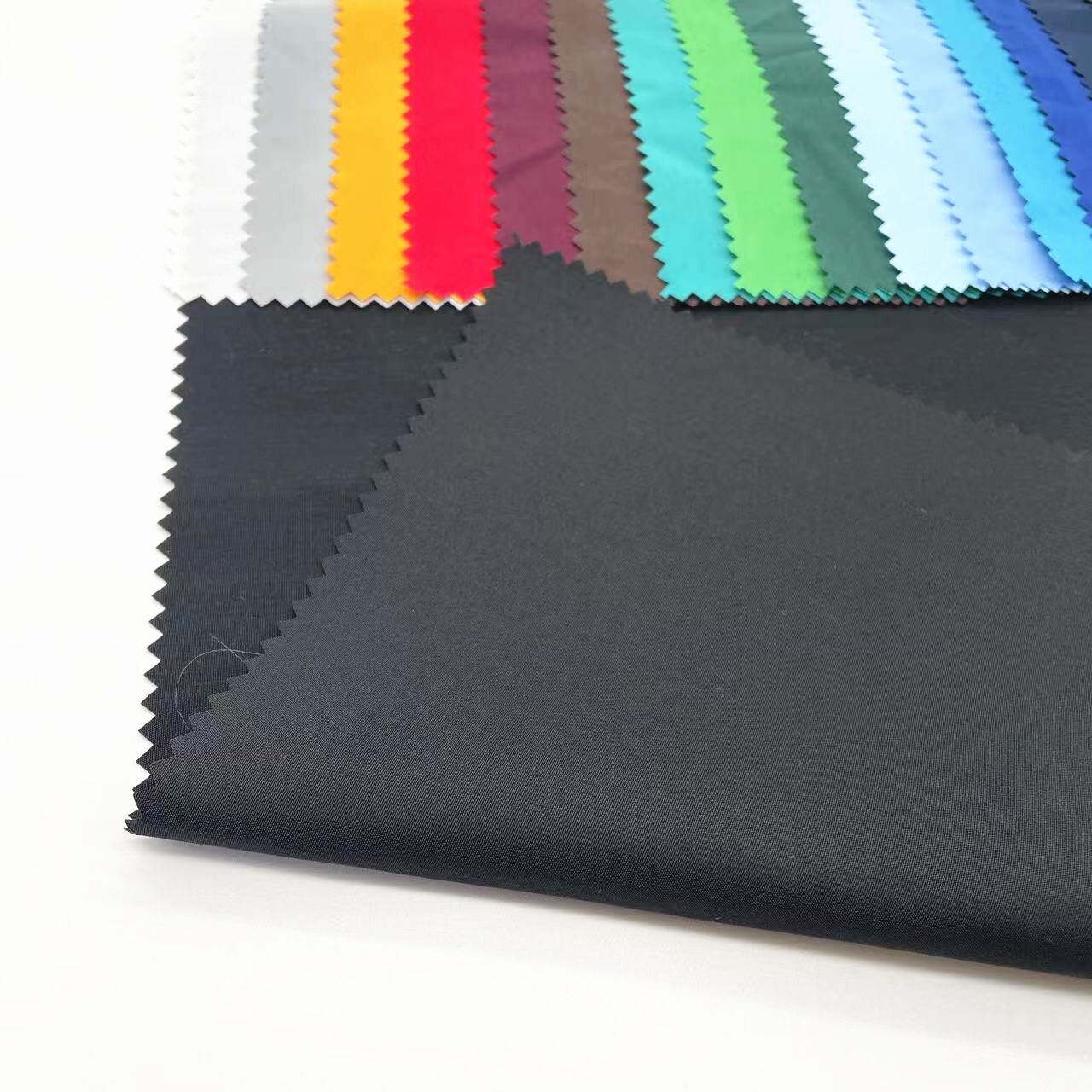

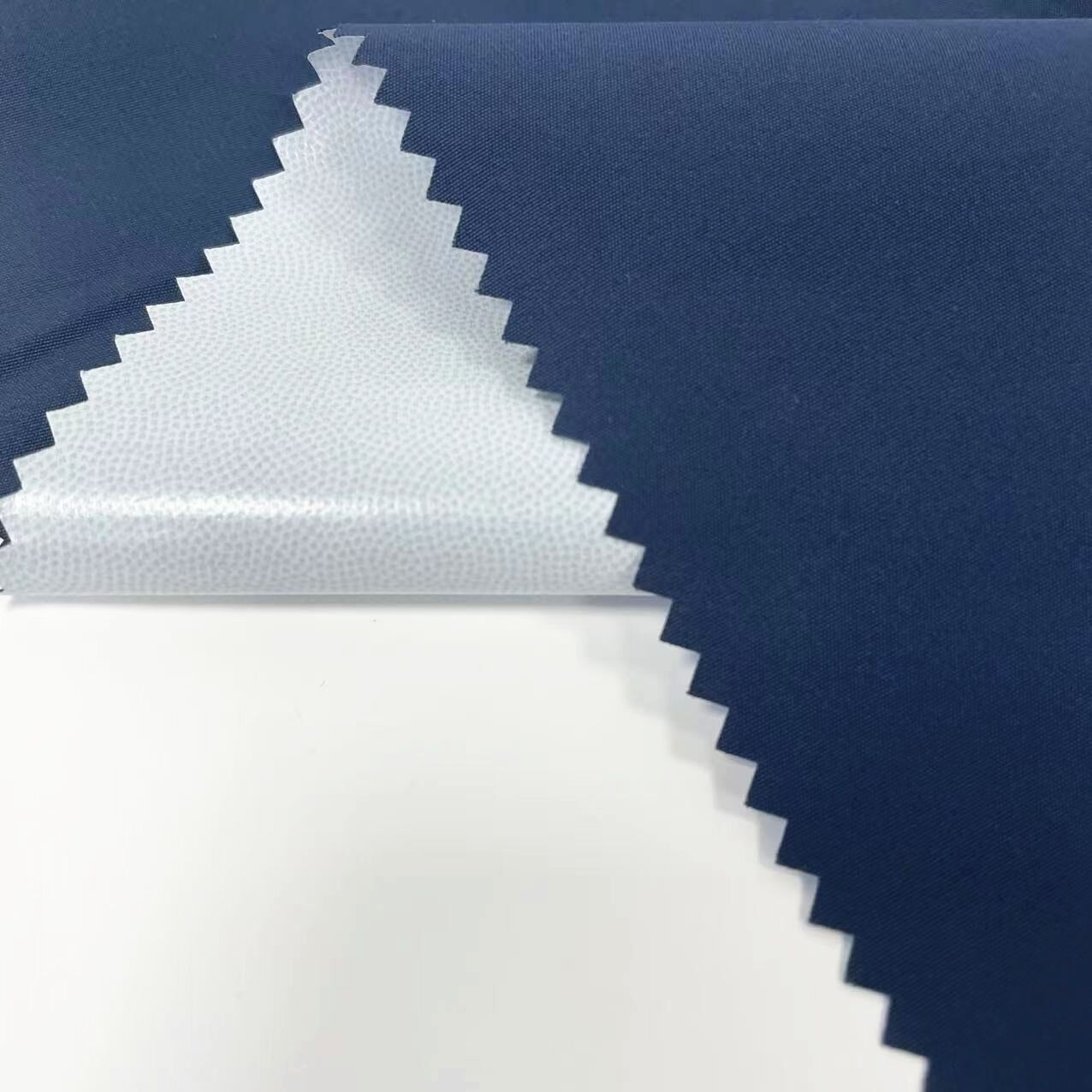

nylon ripstop 210D dengan lapisan PU dan Dyneema

| Konten: | Nilon |

| Lapisan: | PU(Poliiuretan) |

| Negara asal: | China |

| Tenun: | TANJUNG |

| Kuantitas Pesanan Minimum: | 1000Yard |

| Lapisan yang tersedia: | PU/PVC/TPE/TPU/ULY |

| Detail Kemasan: | 100yard/roll |

| Waktu Pengiriman: | 20-25 hari setelah menerima uang muka |

| Ketentuan Pembayaran: | 30% T/T diperkirakan, 70% melawan salinan B/L |

| JenisPenyediaan: | Buat sesuai pesanan |

- Parameter

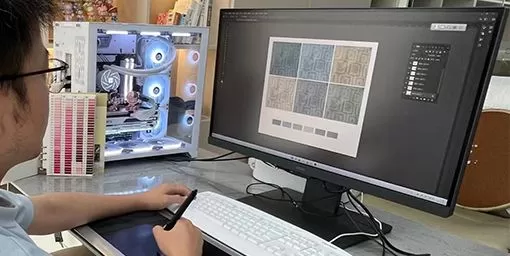

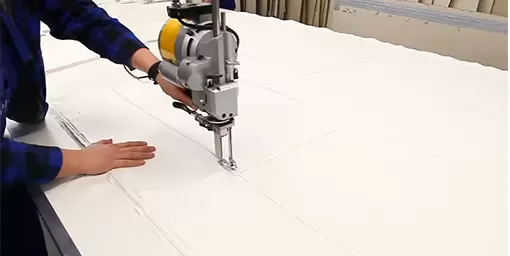

- Alur proses

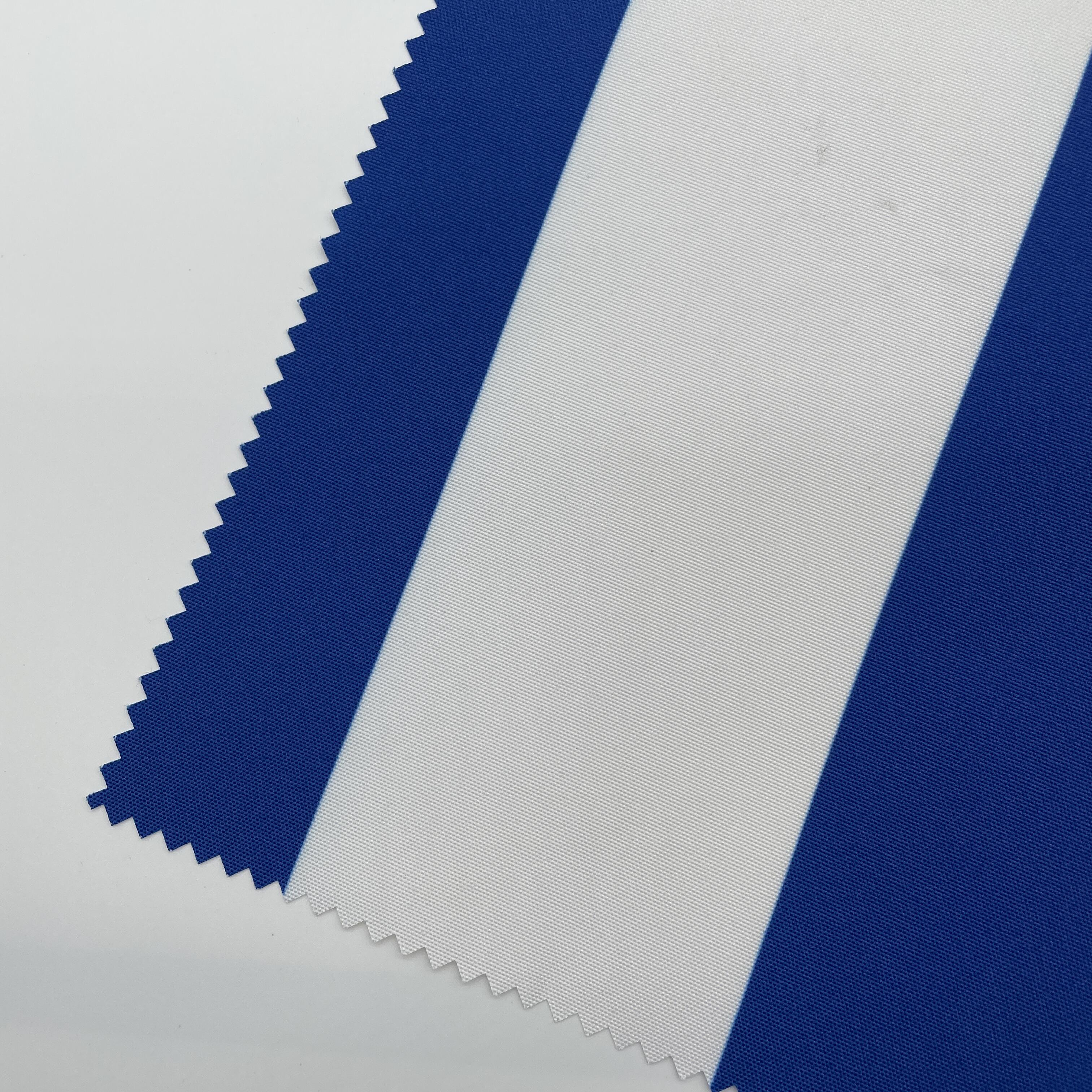

- Produk terkait

- Inquiry

Parameter

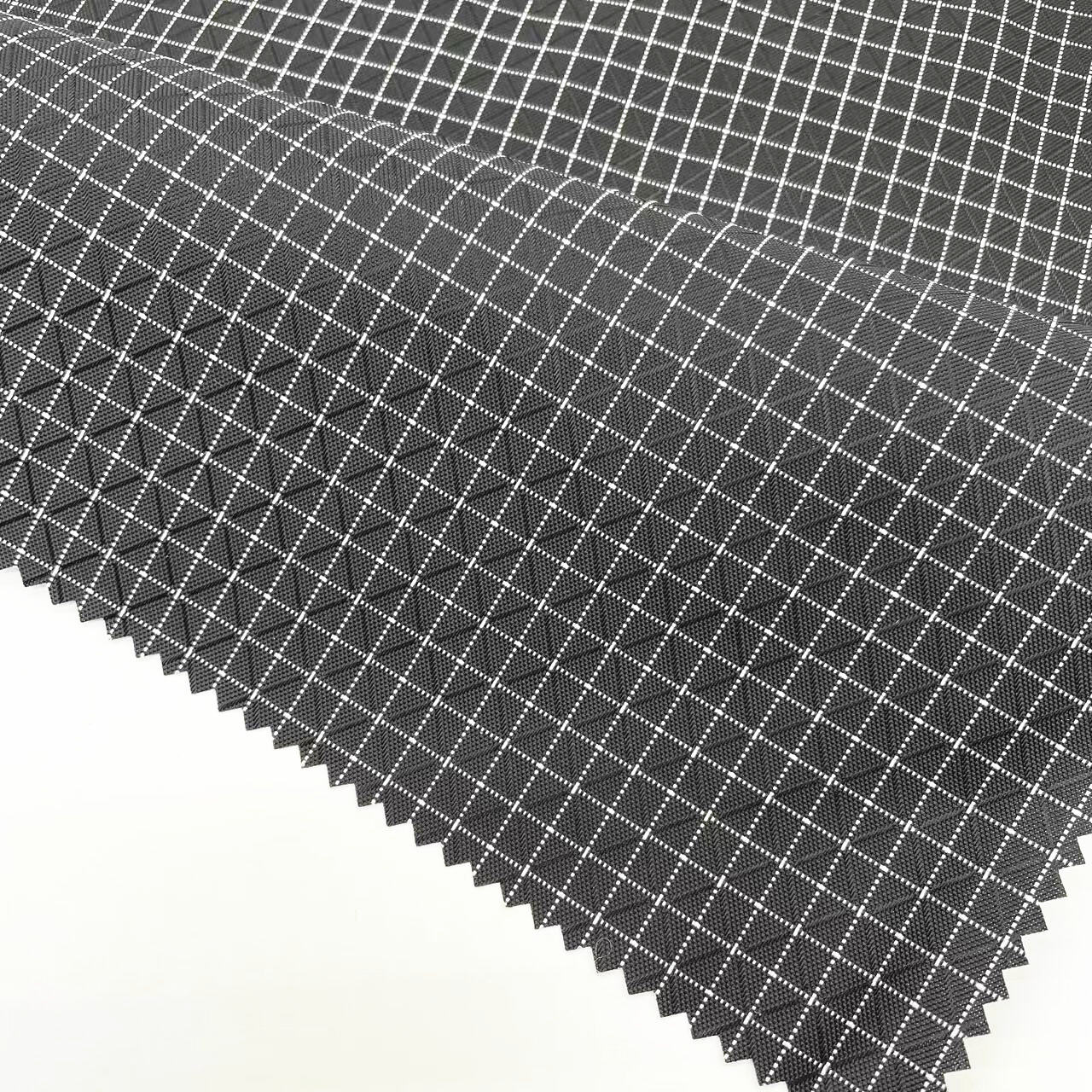

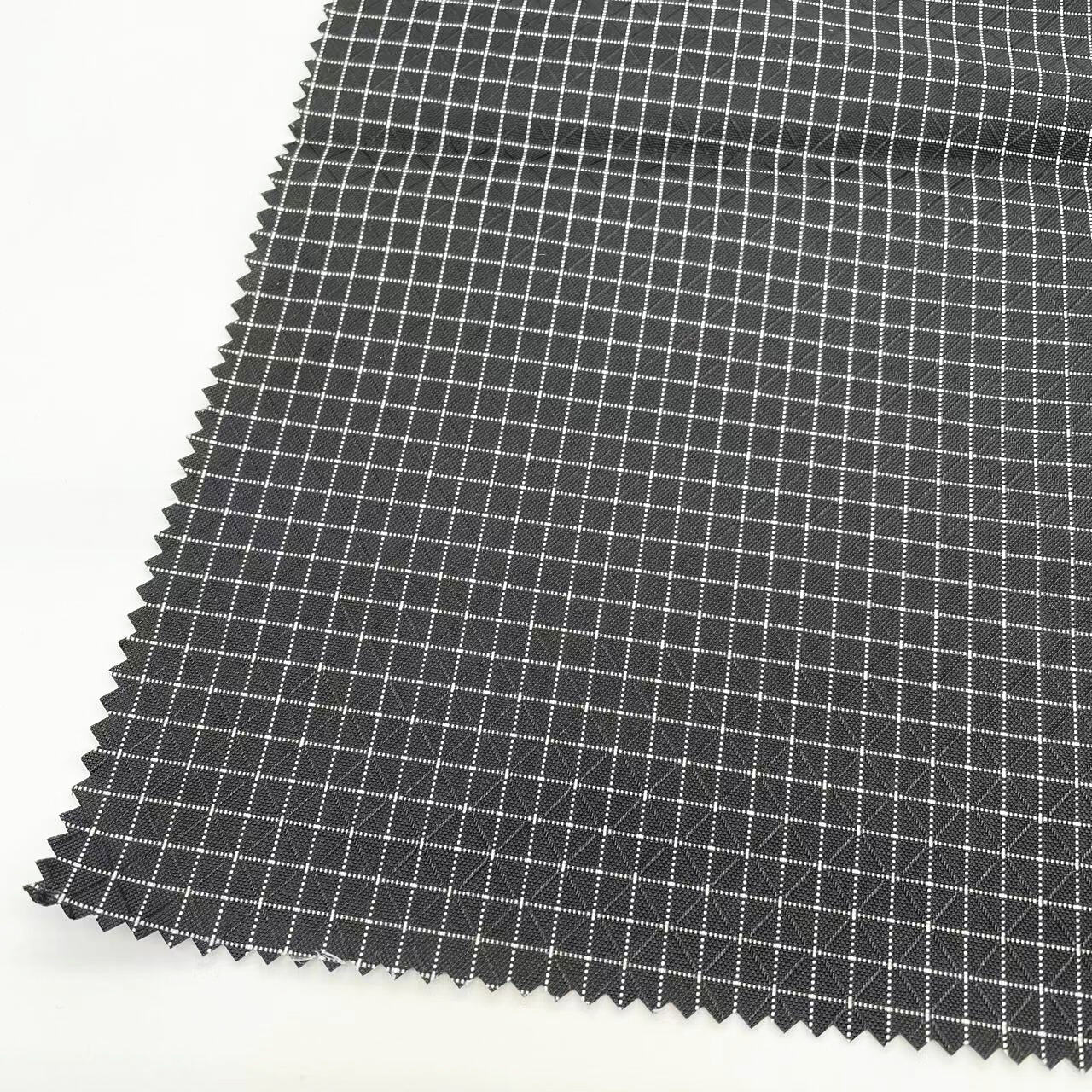

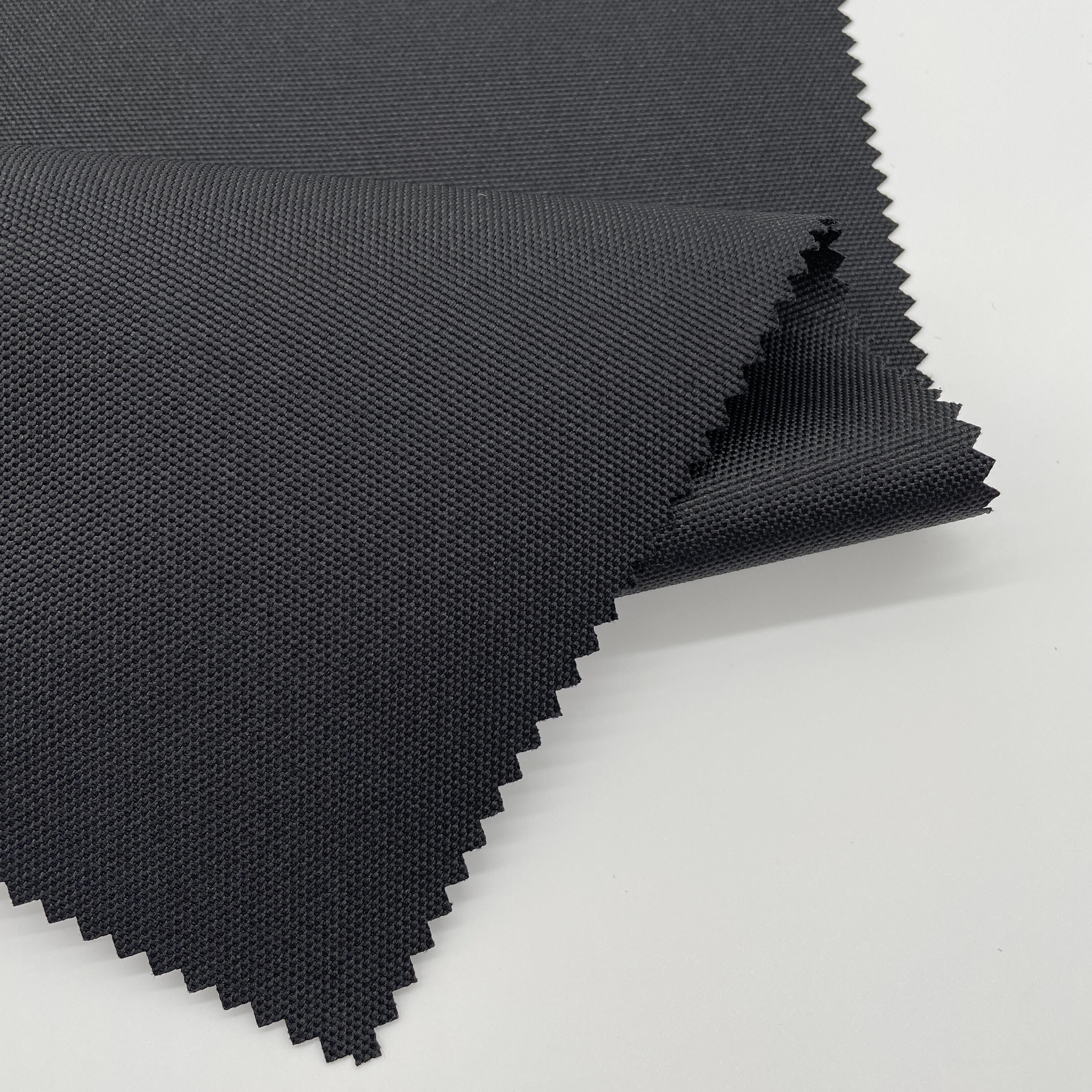

Kain anyaman nilon 210 Denier berwarna hitam ini mengandung ripstop Dyneema® berwarna putih. Kandungan Dyneema® setara dengan sekitar 9% dari berat total kain.

Rahasia kinerja unggul serat Dyneema (UHMWPE) terletak pada rantai molekul yang sangat panjang ... W PE) terletak pada rantai molekul yang sangat panjang yang mentransfer beban secara lebih efektif ke rangka polymer. Sebagai hasilnya, Dyneema menawarkan kekuatan maksimum dengan berat minimum. Ini bisa hingga 15 kali lebih kuat daripada baja berkualitas dan hingga 40% lebih kuat daripada serat aramid, baik itu berdasarkan bobot per bobot.

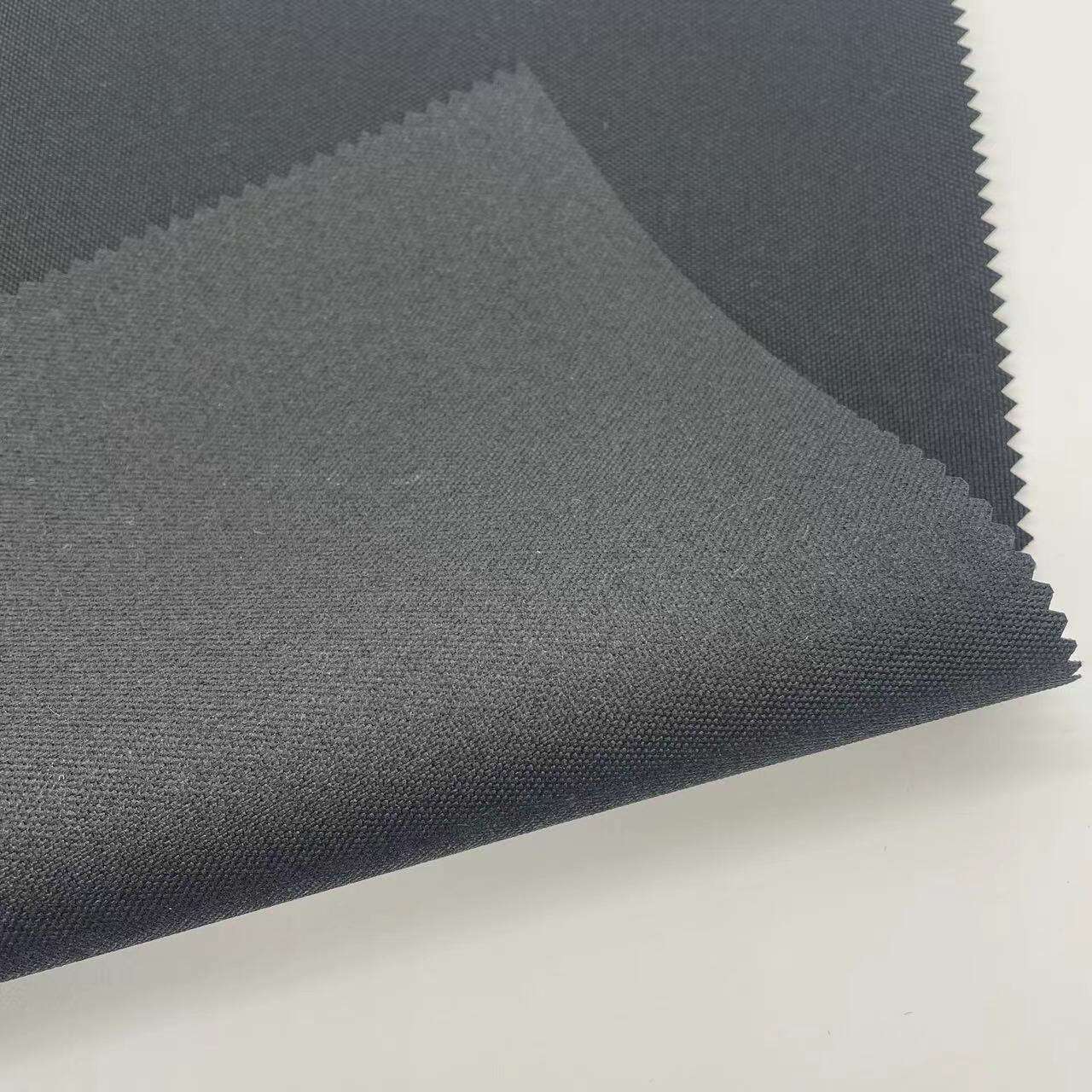

Kain Dyneema ini memiliki lapisan polyurethane di sisi belakang dan tahan air finishing tahan air di permukaannya yang membuatnya sangat tahan terhadap air.

Dyneema ripstop sangat cocok untuk ransel, tas pakaian, tas perlengkapan, dan aplikasi lain di mana kekuatan tinggi dan berat rendah menjadi prioritas.

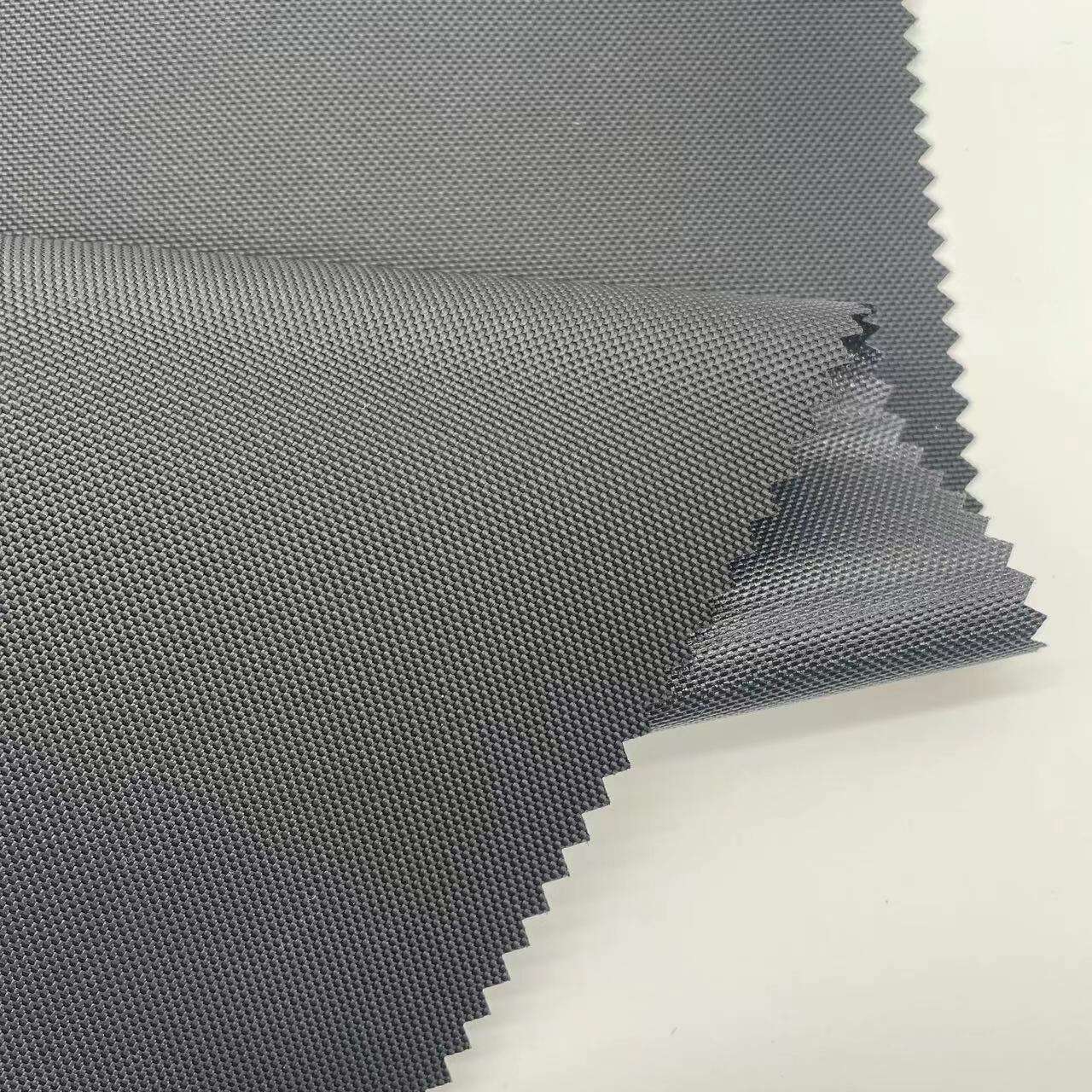

Gridstop 210D yang sama yang telah kita kenal dan sukai selama bertahun-tahun, sekarang tersedia dengan Dyneema® .

Bahan populer untuk ransel ini dibuat lebih kuat dan tahan gesekan melalui penguatan serat Dyneema Uhmwpe dalam pola grid di atas dasar pola ripstop.

Grid Dyneema juga menghasilkan kekuatan tarik dan tensile yang luar biasa dibandingkan dengan banyak kain 100% nilon atau poliester tanpa penguatan.

Aplikasi:

210D Nylon Oxford sangat cocok untuk peralatan outdoor, barang olahraga, dan bahkan peralatan medis.

Beberapa penggunaan umum kain ini meliputi: sarung penutup furnitur taman atau grill, bendera dan spanduk, tas dengan tali serut, pelapis untuk tas, kotak, tenda, dan hammock ,daerah penguatan .

| Benang: | 210D*210D | ISO 7211\/5 |

| Komposisi: | 91%Nylon, 8%UHMWPE | ASTM D629 |

| Tenunan: | tANJUNG | Visual |

| Kepadatan(in): | W215*F88 | ISO 7211\/2 |

| Finishing: | Lapisan DWR+PU | Visual |

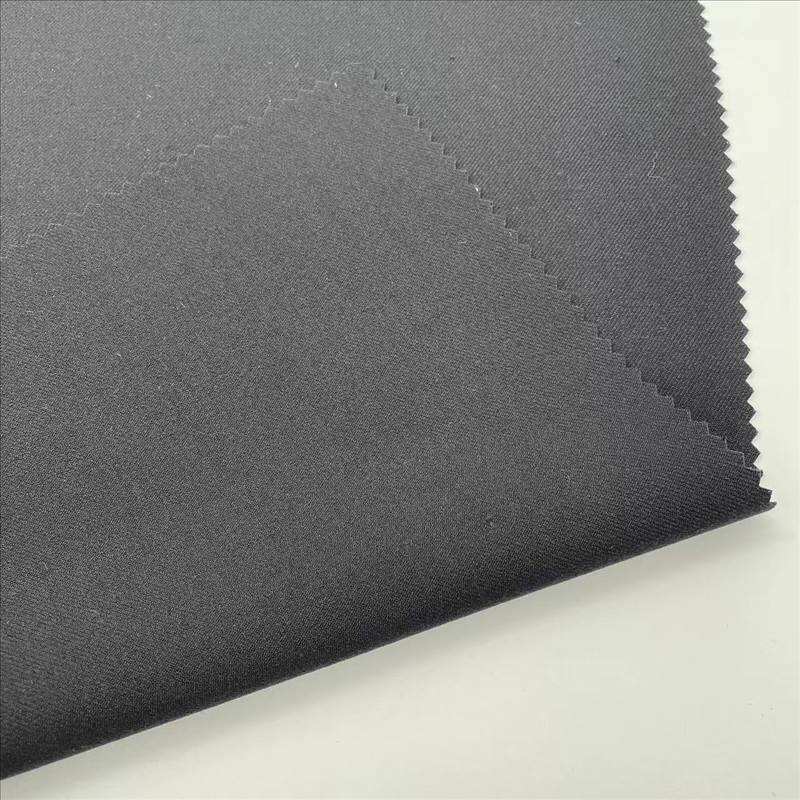

| Ketebalan: | 0.12mm | ASTM D 1777 |

| Lebar: | 60’’ | ASTM D 3774 |

| Berat: | 2,5 oz/sq yd | ASTM D 3776 |

| Penilaian semprotan: | 95% | AATCC TM22 |

| Kekuatan sobek: | W:20LBF, F: 15LBF | ASTM D1424 |

| Kekuatan tarik 1'': | W:287LBF, F:240LBF | Uji Pegangan ASTM D5034-21 |

| Ketahanan terhadap gesekan : | 143rubs | ASTM D3884-0 Roda tahan lama: H18, beban:500g |

Keunggulan Kompetitif:

Kualitas Tinggi

Harga langsung dari pabrik

Pelapis anti air tahan lama

Ketahanan warna yang excellent

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

HY

HY

UZ

UZ